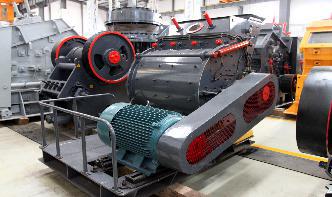

spout feeder ball mill inlet chute

jamming of the coal chute from the bunker due to high moisture in 16 Aug 2013 ... Coal inlet temperature. ... jamming of coal chute from bunker due to high ... Coal Mill: ContentsDataModel: VM130M ... spout feeder ball mill... Get Price. Buried In Grain NPR News Apps