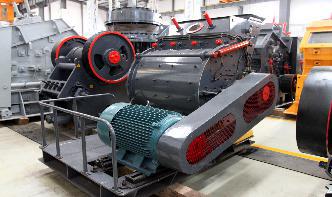

Autogenous and SemiAutogenous Mills | FL

Rely on our proven track record of SAG and AG Mill superiority. Since the early 1980s, we have been designing and manufacturing SemiAutogenous (SAG) and Autogenous (AG) Grinding Mills under the FullerTraylor brand. Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore only.