Rod mill|Rod mill manufacturer|Grinding rod mill price|Ore ...

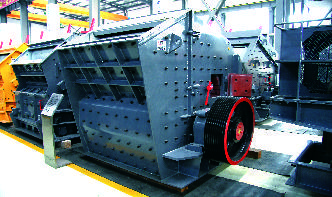

Grinding rod mill can be classified into ore rod mill, wet rod mill and so on. Grinding rod mill is mainly used in the preparation of the coal chemical industry, quartz sand, silica sand, sand filling, tungsten ore, potassium and sodium feldspar, bauxite and other industries.