Inline/ Linear Feeders | Feeding Concepts Inc.

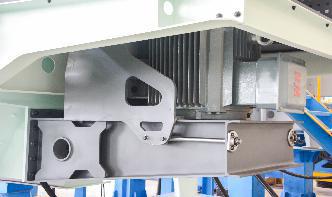

Once the part exits the vibratory feeder it then proceeds across the straightline linear feeder into the customers machine. An inline/linear feeder can range anywhere from 6" all the way up to 48" or higher. depending on the application. Our precision machinists will construct the track to meet your required orientation. The track is formed