![How Does a Hammer Mill Work? [Slideshare] | Schutte Hammermill](/e69yszg/555.jpg)

How Does a Hammer Mill Work? [Slideshare] | Schutte Hammermill

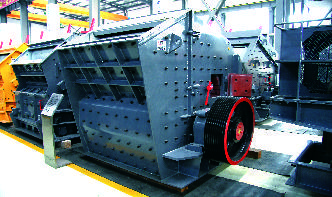

Oct 01, 2014· Hammer mills work on the principle that most materials will shatter upon impact.

![How Does a Hammer Mill Work? [Slideshare] | Schutte Hammermill](/e69yszg/555.jpg)

Oct 01, 2014· Hammer mills work on the principle that most materials will shatter upon impact.

The discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding area. Roller Mills. A combination of cutting, attrition, and crushing occurs in roller mills.

Creating a part on a CNC mill is a three phase process. The part is drawn in a CAD (Computer Aided Design) drawing program such as AutoCAD. Then a CAM (Computer Aided Manufacturing) program is used to convert the CAD drawing to GCode. Finally, the Gcode controls the CNC mill as it makes the part.

Designed for ease of use, adjustment, and maintenance, the DeMuth Roller Mills feature a single, "no tools" adjustment point to vary the degree of grain reduction. A simple snap pin maintains the proper adjustment. Power requirements are reduced because non synchronous roll speeds shred or grind the grain instead of compressing it.

May 15, 2013· The solution is to stabilizethe particle size of materials into the vertical roller mill, theappropriate adjustment of feed rate or reduce the grindingpressure, the assurance required under the premise of thefineness of materials, appropriate to reduce the classifier speed.(2) Metal piece into the vertical roller mill, check the metaldetectors

Historically: How to Site a Mill by Theodore R. Hazen. ... The vertical mill wheel made it necessary to build a gear system to change the horizontal rotation of the main shaft into a vertical motion that could be used inside the mill to power the millstones. ... which incorporated the New Process milling system and the use of the "ROLLER PROCESS."

![How Does a Hammer Mill Work? [Slideshare] | Schutte Hammermill](/e69yszg/3.jpg)

Oct 01, 2014· Hammer mills work on the principle that most materials will shatter upon impact.

parameters, and relative costs to acquire and to operate. Roller Mill Grinding Roller mills have been used in the processing of common feed materials for years. The earliest roller mills used in the feed milling were abandoned flour milling roll stands, used primarily .

The revolving vertical spindle of the drilling machine holds and drives the cutting tool. In order to use various sizes and shapes of drills in various machines three types of drill holding devices, which fit the spindle of the drilling machines, are used: the geared drill .

Feb 03, 2020· Step 1, Clean all surfaces, for example table, vise jaws and part very good with a lint free 2, Load tools needed. (including edge finder)Step 3, Load part in vise or however your work holding is going to be. [2]

Jun 01, 2019· Spread your roller blinds out on a flat and clean surface. You need a large, flat surface to mark your cuts. A large table or clean section of the floor will work just fine. Open your blinds all the way and place two heavy objects at either end so that they don't retract and lie flat on your work surface.

Poorly modified malts will adhere to the husk as hard ends, whereas fully modified malts will more readily separate from the husk with a tworoller mill. The Workings of a Mill . If you wish to construct or purchase a tworoller mill, keep in mind that its design must yield a highquality crush within a reasonable amount of time and effort.

When using a vertical miller, the machine should be set up to cut away only a small amount of metal each time the cutter passes over the surface of the metal. A wide selection of cutting tools are available. They are made from high speed steel and are strong enough .

How To Operate Vertical Roller Mills. Increasing cement grinding capacity with vertical roller mill technology With the many largescale plant expansions made in the US in recent years there has been a need to use new and complex burning and emission control

Use our simple installation instructions and videos to install your custom Bali Blinds and shades.

How the Sawmill Works. Below is a schematic diagram showing mechanism of the Ledyard sawmill. Click on it to enlarge. Following the diagram is an explanation of each of the subcomponents with recent photos and videos of the actual machinery.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Dec 19, 2009· I've just bought a couple of roller blinds from Dunelm Mill. They were quite cheap and now I can see why! The mechanism that winds them up and down is not up to much .

Gelatinization occurs by mechanical means such as grinding, pressure, and by hot water. Soft feed at an environmental temperature of 25°C can be brought to a temperature of 85°C by the addition of 4 to 6 percent moisture from steam. Frictional heat due to passage of feed through the pellet mill adds 2...

According to the thermal discharge of sulfur dioxide to the atmosphere, combined with China's national conditions and the demand of the market at the same time, our company production have environmental effect of new type of vertical roller mill, it is small and mediumsized ball mill. Vertical roller mill developed by my company is suitable for various large and mediumsized coalfired power plant .

LM Vertical Grinding Mills Selling point. reliable operation: automatic control system installation, can realize remote control, simple operation. high performance: hot air in direct contact with the material in grinding, drying capacity, saving energy (for the mill system saves a dryer).

The panel guides the workpiece towards a vertical spindle, which only moves in the Z (vertical) axis. Movement in the X and Y axes is taken care of by the panel holding the workpiece. The single spindle used in CNC vertical machining centres is robust and highly durable, which ensures wear and tear is kept to a minimum. This system makes the ...

LOESCHE has now been able to provide a vertical roller mill of type LM +3 CS for grinding cement clinker to its end customer Attock Cement Pakistan Limited (ACPL). The new mill will be used in the new line 3 of the cement plant in Hub Chowki in Pakistan, in the Lasbela/Baluchistan district, 20 .

MILLING MACHINES Knee type Vertical and Horizontal Mills with optional digital readouts, power feeds, etc. CNC MILLING MACHINES Available in 2 Axis with Z axis digital readout and full 3 Axis CNC or 4 axis with rotary table. CNC BED MILL MACHINES Large bed type Vertical Mills for heavy parts. ...