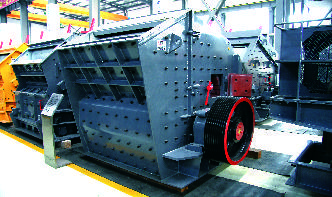

Primary Crusher Selection Design

The crusher capacities given by manufacturers are typically in tons of 2,000 lbs. and are based on crushing limestone weighing loose about 2,700 lbs. per yard3 and having a specific gravity of Wet, sticky and extremely hard or tough feeds will tend to reduce crusher capacities.