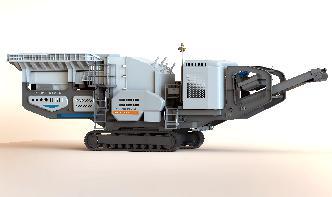

Toggle Angle Effect On Jaw Crusher

jaw crusher design moving jaw degree Jaw crusher includes large heavy jaw crusher and small jaw crusher. If you want know more about jaw ... Toggle Angle Effect On Jaw Crusher... >>TYY LXP. effect a nip angle in a gyratory crusher