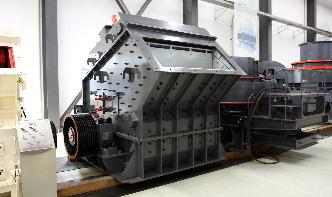

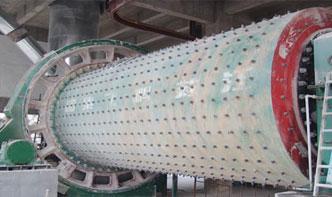

Cement Production LineChina Henan Zhengzhou Mining ...

High Efficiency. Cement production line adopts advanced technology and equipment to raise technical level and to ensure design indexes. New fivestage cyclone preheater system, high efficiency air girder grate cooler, multipassage pulverized coal burner, Davison heat temperature fan, jet pulse dust collector, as well as chainboard elevator, chain conveyor adopted in this production line can ...