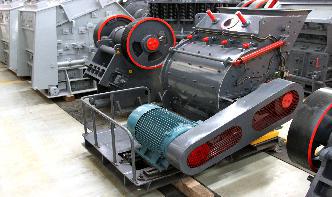

The main components of the ball mill Bestcrushers's blog

Earlier in the overall structure of the several types of mill. The following will introduce the basic structure of the main components of the mill. Rotary. Rotary parts include: cylinder,energysaving grinding plant grinding head (end cap and hollow shaft), linings, diaphragm plate, blocking balls circle parts.