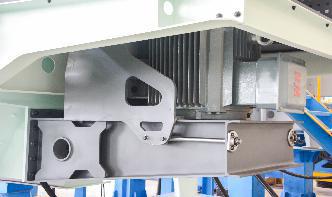

Weldon Solutions CNC Grinders

All Weldon CNC grinders can routinely and automatically grind contours, tapers, chamfers, fillets, radii, shoulders, and straight diameters in one setup and one continuous operation. They have the capabilities for OD/ID work in one setup; ID contouring; and nonround grinding... all with excellent results in productivity and quality.