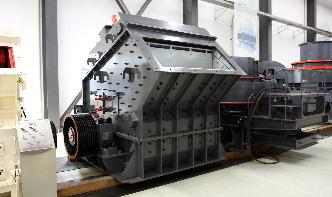

Parts of Raymond Milling Plant, Introduction Of Raymond ...

This grinding mill perfectly satisfies the production demands of the customers on 20033μm (80425Mesh) fine powder. MTM Mediumspeed Grinding Mill MTM grinding mill absorbs world firstclass industrial powder milling technology and organizes the technical experts and related engineers for elaborate design, test and improvement.