Kolomela Iron Ore Mine, Northern Cape Mining Technology ...

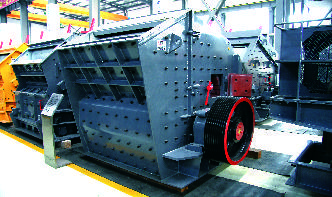

Kolomela mine produces 64% Fe lump and % Fe fine ore. The mine produced of direct shipping iron ore in 2013 with a stripping ratio of The cash cost per tonne produced during the year was Iron ore mining and processing at Kolomela