LABORATORY MANUAL IITK

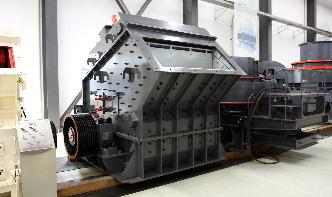

LABORATORY MANUAL MANUFACTURING PROCESSES ... (Excluding standard parts) ... OBJECTIVE: To study the characteristic features of Milling machine. OUTLINE OF PROCEDURE i) Run the machine at low speed and observe the motions, which control the shapes of the surfaces .