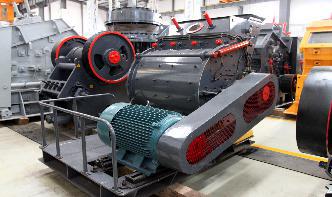

DESIGN, FABRICATION AND TESTING OF A LABORATORY .

hammers was used to avoid the rotor or the hammers from getting stocked in case a hammer comes in contact with a material it cannot break at first impact. Design theories and Calculations Determination of Shaft Speed To calculate the shaft speed the following parameters are .