Impact Crusher an overview | ScienceDirect Topics

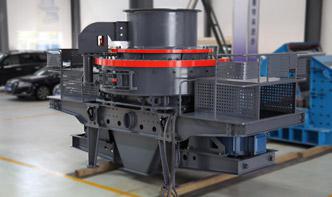

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force and crack is avoided. Compared with hammer crusher, the impact crusher is able to .