Crushed Granite vs Pea Gravel: Pick the Right Material for ...

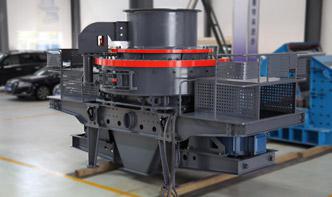

Pea gravel becomes smooth either naturally, by exposure to running water, or through a great deal of polishing. Crushed granite involves granite being harvested, pulverized, screened to size and washed to remove impurities. Size/Shape. Pea gravel is always round and approximately the size of a large pea.