Clay Processing US EPA

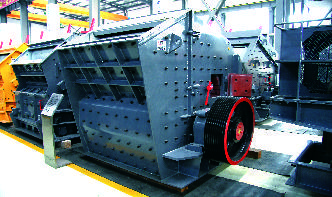

crushers, smooth roll crushers, toothed roll crushers, and hammer mills are used for secondary crushing, which further reduces particle size to 3 mm ( in.) or less. For some applications, tertiary size reduction is necessary and is accomplished by means of ball, rod, or pebble mills.