Steelmaking,Steel Rolling Mill,Steel Finishing Machine ...

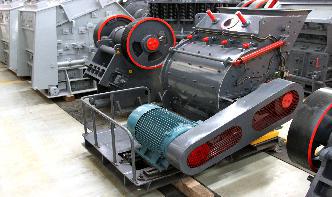

Dongchen is professional manufacturer of steel fine finishing machinery and grinding equipment in China. We mainly produces billet or slab continuous casting machine, different kinds of steel rolling mill machinery including steel tube rolling mill machines, steel fine finishing machinery for bar, billet, tube billet, and various kinds of precision grinding equipment for square and flat billet ...