Rock Crushing Screening Plants Screen Machine Industries

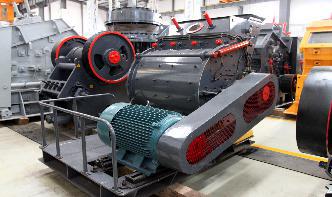

CST Cone Rock Crusher The CST Cone Crusher is a medium to large size track mounted portable crusher plant designed for secondary crushing of hard rock into cubical sizes. Featuring a heavybuilt "Quarry Duty" cone crusher, the CST is perfect for rock quarries and other mining operations.