How To Recycle Concrete |

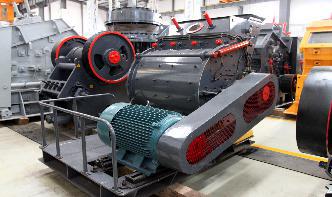

Recycled concrete is sometimes used as an aggregate for creating new concrete but is more often used as an aggregate in sublayers of concrete. How to Get It Done A variety of difficulties, such as removing metal reinforcements and crushing equipment able to handle steel reinforcements, have existed when recycling concrete.