Home | Crushing and Screening Equipment |

is a manufacturer of aggregates and mining crushing and screening equipment with a continuous devotion to meeting the needs of our customers.

is a manufacturer of aggregates and mining crushing and screening equipment with a continuous devotion to meeting the needs of our customers.

The Patriot® Cone Crusher Plant allows you to take advantage of exceptional crushing capabilities via our patent pending Superior Vantage Automation® in a fullyfunctioning portable operation. The plant chassis is equipped with an air brake system, toolbox, hydraulic leveling legs, fixed structural cribbing legs, king pin supports, and diamond plate walkway with drainage holes.

Print Results. KPIJCI and Astec Mobile Screens does not warrant information obtained from this calculator to be used or relied upon for any specific application without examination of the application and results by KPIJCI and Astec Mobile Screens.

The capacity is a function of size and OSS. Manufacturers publish tables of capacity for their crushers of various size as a function of the openside set. Cone crushers Cone crushers are commonly used for secondary, tertiary and quaternary crushing duties.

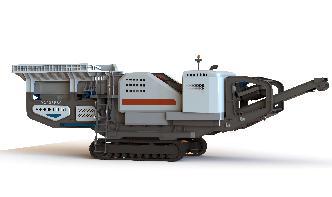

The MOBICONE MCO 11 PRO mobile cone crusher stands out thanks to its extremely robust design and impressive performance. As an option, the plant can be operated using an external power source and it requires impressively little maintenance.

The cone crusher (a compression type) simply crushes the aggregate between the oscillating cone and the crusher wa ll (Figure 59). Clearance settings on this equipment are required to be checked and maintained as part of standard operating procedure. Figure 59. Cone Crusher

The operation is similar to the standard cone crushers, except that the size reduction is caused more by attrition than by impact . The reduction ratio is around 8:1 and as the product size is relatively small the feed size is limited to less than 50 mm with a nip angle between 25° and 30°.

The operation test of the CJC Fine TM Filter in crusher #2 showed, after 6 hours of filtration an ISO cleanliness class 15/12/9. At the same time sampling was made after the filter to check the equipment efficiency in one pass and amazing code ISO 13/10/7 was seen. Maintenance Manager Renato Salvo Ravioly was very satisfied with these

The Sepro Blackhawk 100 Cone Crusher is a modern, hydraulically operated cone crusher designed to be simple, rugged and effective for heavy duty mining and aggregate applications. The combination of the speed and eccentric throw of the crusher provides fine crushing capability and .

Cone crusher, Cone crushers, Cone crusher manufacturer,CS Cone crusher supplier,CS cone crusher ... And the gear and pinipn with high strengh and high precision are adopted to ensure the reliable operation of equipment. (2) Main shaft: Forged form hardened and tempered chrome molybdenum steel particularly large diameter to suit wear ...

Stone crushing plant mainly includes vibrating feeder, jaw crusher, cone crusher, impact crusher, vertical shaft impact crusher, vibrating screen, belt conveyor, electric control panel, etc. It could crush and screen various materials such as limestone, marble, granite, basalt, river stone, etc to produce sand and gravels for construction with ...

Cone Crusher Modelling and Simulation, of existing crushers in operation for eg optimization purpos The platform is based on the Discrete Element Method (DEM), Cone crushers are the most commonly used crusher type for secondary and tertiary crushing. cone crushers operation dreamhillscoza

Cedarapids cone crushers set the standard for production and efficiency. Our range of powerful cone rushers boast all the latest features, from hydraulic tramp iron relief systems, to automation and telematics systems. RC45III Hydraulic Adjustment System Allows .

The most efficient cone crusher on the market. The Sepro Blackhawk 100 Cone Crusher is a modern, hydraulically operated cone crusher designed to be simple, rugged and effective for heavy duty mining and aggregate applications. The combination of the speed and eccentric throw of the crusher provides fine crushing capability and high capacity in a very compact design.

Widely renowned as Aggregate Crushing Specialists, Tesab manufacture a Crusher Range to suit any operation. Offering Jaw Crushers to Crush Primary Rock, Impact Crushers for Primary, Secondary Tertiary applications and a Cone Crusher to complete the range, Tesab provide customers with a complete solution for any Crushing Application.

cone crusher operation manual – Coal processing system . Jaw crusher maintenance and operating manual before the operation or maintenance of jaw crusher, make sure you have studied manual and received training in safe, .

Description of Operation. A cone crusher is generally used as a secondary crusher in a crushing circuit. Precrushed product (usually 3in minus depending on the cone crusher model) is fed through the top of the cone crusher and flows over the mantle.

Static Cone Crusher Cedarapids cone crushers set the standard for production and efficiency. Our range of powerful cone rushers boast all the latest features, from hydraulic tramp iron relief systems, to automation and telematics systems.

Nov 25, 2019· The cone crusher is one of the most common ones and often used as the secondary crushing machine in the whole stone crushing process. Cone crusher working site. During the operation of the cone crusher, the operator often encounters a variety of problems.

In Mineral Processing Design and Operations (Second Edition), 2016. Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1].The smaller form is described as a cone crusher. The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly ...

HE MODE OF OPERATION The cone crusher reduces the feed material by means of pressure The adjustable gap width can be varied by a hydraulic piston, which is loed in the lower part of the housing The upper section of the housing acmodates the wedgeshaped crushing tools The crusher drive is situated Spring Cone Crusher Working Principle YouTube

A cone crusher that is under fed causes the cone to be overloaded, causing concentrated wear of the bowl and mantle liners. Overloading of the crusher by incorrect feed material can also cause damage to the crusher's internal bushing.

Pilot Crushtec International (Pty) Ltd is South Africas leading supplier of mobile and semimobile crushing, screening, recycling, sand washing, stockpiling, compacting and material handling solutions. Our product range includes jaw crushers, cone crushers, vertical shaft impact (VSI) crushers, impact crushers, screens and conveyors.

US440E Mobile cone crusher US440E mobile cone crusher is a highly efficient electrically powered, trackmounted complete process machine with a cone crusher and screen onboard. It has been designed to meet the demands of quarry operators, construction companies, mining companies or contractors working with highly abrasive materials, and ...