QJ341 Mobile Jaw Crusher – World Leading Jaw ...

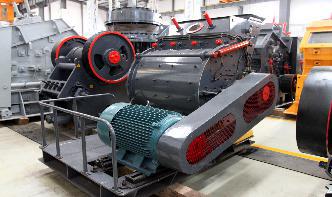

QJ341 mobile jaw crusher is the ideal solution for a wide range of applications. It's equipped with a C12 jaw crusher, a powerful and fuelefficient engine, and is .

QJ341 mobile jaw crusher is the ideal solution for a wide range of applications. It's equipped with a C12 jaw crusher, a powerful and fuelefficient engine, and is .

As the equation for calculating the efficiency of a jaw crusher is a six variable equation set, the results visualization represents no easy task. Chat Now; efficiency crusher calculate sayorain. how to calculate efficiency of jaw crusher How to calculate the weight of a thin plate, its simple to calculate the weight of a thin plate and tubes .

Sep 26, 2019· The issues being faced by the LJ5139 Jaw Crusher, which was tracked and being used in a quarry, were varying in nature. With the machine itself weighing up to 110 tonnes, the chassis is subject to high loads when tracking across the quarry on uneven surfaces.

Jaw crusher is used for crushing all kinds of ores and rocks with compressive strength below 320MPa. It is generally used for primary crushing of materials. The machine is widely used in mining, building materials, metallurgy, electric power, water conservancy, transportation and many other fields.

– Moveable parts: jaw plate, eccentric shaft, bear, belt pulley and other components. The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber.

Mar 19, 2018· The operation and use procedures of jaw crusher Before the jaw crusher is started, the equipment must be thoroughly inspected, for example, to check if the connecting bolts are loose; whether the protective cover of the pulley and the flywheel is ...

Visualization Of How The Jaw Crusher Stone crusher 3d drawings Grinding Mill China retsch jaw crusher supplier in canada CS series cone crusher is applied to cement mill, mining, building construction, road bridge construction, More; leading stone crusher manufacturers in india .

Jaw crusher efficiency calculation ate the efficiency of jaw crusher the term energy efficiency of the crusher is defined as the ratio of the theoretical pq university lesson 7 crushing secondary breaking pit aug 5 2015 output for mobile jaw crushers ranges from 100 to 1500 tph newdesign mobile jaw and impact crushers. More

jaw crusher efficiency calculation nrgsolutionsbe calculate the efficiency of jaw crusher The term energy efficiency of the crusher is defined as, the ratio of the theoretical PQ University Lesson 7 Crushing Secondary Breaking, Pit Aug 5, 2015 Output for mobile jaw crushers ranges from 100 to 1,500 tph Newdesign mobile jaw and impact . chat online

jaw crusher drawings jaw crusher drawings sapeduin. Drawing Crusher PlantStone Pulverizing, Crusher Plant Autocad Drawing Grinding Mill China Autocad files of crushing machinery foundation jaw crusher plant in . Mobile Crushing Plant Autocad Block kindercafe . Mobile Crushing Plant Autocad Block.

Jaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw. The swing jaw being the moving part is attached to a rotating eccentric shaft. The fixed jaw is an integral part of the crusher frame. Both jaws are fitted with manganese jaw liners that can be replaced or reversed when worn.

CJ612 singletoggle jaw crusher is engineered for even the toughest applications thanks to its heavyduty design. Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost.

Jaw Crushers. Jaw Crushers are used to reduce the size of many different types of materials in many applications. The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher. Introduced in 1906, McLanahan's Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers.

The Laboratory Jaw Crusher Pulverisette 1 is recommended for intermittent or continuous precrushing of coarse materials. The maximum feed size is approximately 60 mm (model I) or 95 mm (model II). The maximum throughput is140 kg/h (model I) or 200 kg/h (model II). The optimum fineness depends on the gap setting which can be set from 15 to 1mm.

"Successful jaw crusher maintenance requires the right resources, the right tools and the right approach," says Bill Macini, a service technician.. Certainly when an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possible.

Nov 14, 2015· Figure 1 Jaw Crusher Design of Jaw Crusher As jaw crusher is designed to impart an impact on the solid particles placed between a fixed and a moving plate. The faces of the plate is made up of harden steel, both plates could be flat or the fixed plate and the moving plate convex.

Ultimately, the mining sequence will certainly impact the primary crusher selection. Where you will mine ore and where from, is a deciding factor not so much for picking between a jaw or gyratory crusher .

A better solution would be to use a larger jaw crusher set at 1in, then a roll crusher from the Roll Crusher capacity Table above could be used If the output of this crushing process should have less material of the +1in size, the larger crusher could be operated with a closed circuit. chat online

Compared with traditional jaw crusher, CJ series jaw crusher adopts highstrength material and firstclass manufacturing process. It has the advantages of excellent structure, reliable performance, higher crushing ratio, larger capacity and lower cost.

Jaw CrusherJaw crusher, the most popular crusher in traditional stone crushing plant, is always used in both primary Crusher and secondary crusher manufacturers,jaw crusher in china,100tph jaw crusher price,cost. Welcome to China First Enginnering Technology Co.,Ltd [email protected] .

CJ815 Jaw crusher CJ815 singletoggle jaw crusher is engineered for even the toughest applications thanks to its heavyduty design. Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost.