Mechanical and plant engineering – premium materials for ...

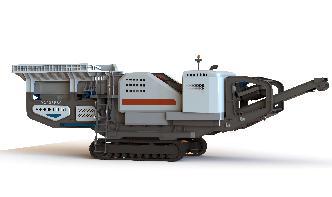

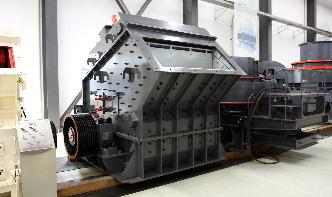

Mechanical and plant engineering – premium materials for stateoftheart processing technologies. For the engineering sector, accessing new markets is a challenge because the playing field is changing. ... This innovative solution is in demand both for mining equipment and for steel and cement production plants.