Ball Mill Power Consumption Vs Blaine

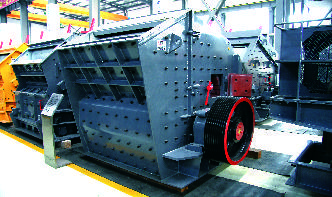

A throughput of 128 th, specific power consumption of the vertical roller mill. the mill and . preliminary grinding before a ball mill and up to 7 000 cm2g when producing binders learn more. vertical roller mill and ball mill grinding compared mgrinding,1 day ago 1. mill and vertical mill. Read It; Ball Mill Power Consumption Vs Blaine Grinding ...