Global Iron Ore Industry | Markets Insider

Aug 06, 2018· Table 5: Iron Ore Pricing Scenario (): Historic and Recent Past Average Prices of Iron Ore in US per Dry Metric Ton (includes corresponding Graph/Chart) Global Iron Ore .

Aug 06, 2018· Table 5: Iron Ore Pricing Scenario (): Historic and Recent Past Average Prices of Iron Ore in US per Dry Metric Ton (includes corresponding Graph/Chart) Global Iron Ore .

Carvalho, in a conceptual study on the technical and economic viability of the synthesis gas for the pelletizing of iron ore in an indurating traveling grate, investigated the usage of gasification in iron ore pelletizing process. Gasification equipment was studied for a pelletizing plant with annual production capacity of million tons of ...

The limit values of the Tumble Index (TI) and Abrasion Index (AI) for the iron ore pellets used in furnace reduction process are >70 wt% for the TI value and <5 wt% for the AI value . It follows from Table 1 that the TI values of Muko ores are between 88 wt% and 93 wt%, which is significantly higher than the stipulated 70 wt%. Therefore, the ores from all Muko deposits can be handled, loaded, and transported .

Iron ore is used directly in the steelmaking process in the blast furnace in the form of lump, pellet, and fines (see Fig. 5). (Fines are converted to sinter feed in a sinter plant.) Iron ore pellets are also used in the production of DRI and HBI.

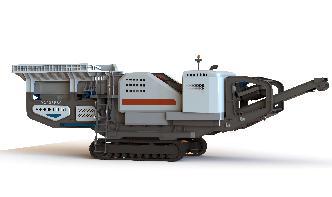

Preparing Iron Ore for Pelletizing (Balling) Iron ore must go through a lengthy preprocessing stage before it can be pelletized – a series of steps that work to beneficiate and concentrate lowgrade ores. This process varies depending on the ore source, but typically involves various stages of crushing and grinding to reduce the size of the ...

Find information for Iron Ore 62% Fe, CFR China (TSI) Futures Quotes provided by CME Group. View Quotes. Markets Home Active trader. Hear from active traders about their experience adding CME Group futures and options on futures to their portfolio. ... Access realtime data, charts, analytics and news from anywhere at anytime. ...

iron ore plant design makers,of iron ore processing equipment and technology for steel makers From plant iron ore plant design iron ore overview An Iron rock is a protruding rock containing iron A player with a Mining level of 15 or higher can mine iron ore from rocks Iron ore mining supplier of iron ore processing equipment and technology for steel makers

Mar 27, 2017· El Garhy Group for Steel to establish USD 200 mn pellet manufacturing plant El Garhy Group for Steel is building a USD 200 mn iron ore pelletizing plant, Chairman Gamal El Garhy tells Al Mal . Once completed, the plant will have a production capacity of mn tonnes of pellets annually, covering the needs of the group's steel rolling mills.

Aug 13, 2014· Pellatization of Iron ores 1. PELLATIZATION OF IRON ORES Muhammed Labeeb 2. Engr 241 Pelletizing is the process of compressing or molding a material into the shape of a pellet Process objective is to transform fine iron ore concentrate into pellets suitable to feed Blast Furnace or Direct Reduction plant or COREX. Palletisation was invented to make use of Blue dust and ultra fine .

Selection and designation of the best compatible product for the plant according to customer requirements. Old Part Configuration Configuration of the old spare parts which are not established any more or are no longer correct.

iron pelletizing equipment manufacturer; compare prices on spice grinder bottles; compare mini plant prices; cost saving ideas for iron ore pelletizing process; comparison of wet grinding with dry grinding pelletizing plant; need establish iron ore pelletizing plant graph or table; compare between sintering and pelletizing; portable sawmills ...

tin table concentrator; ball mills table; charcoal vibrating table; gold concentration table; how to build a concentrating vibratory table for minerals; separating table cassiterite; need establish iron ore pelletizing plant graph or table; bajaj table top wet grinder price list; gold shaker table for sale price in indonesia; table roller mill ...

2006, cement plants produced million metric tons of cement. ... reduces the amount of CKD to be managed outside the kiln, it also reduces the need ..... of the free lime content and ability to enhance the effectiveness of other .... also been used as a binder in pelletizing iron ore fines for recycling in .

Overall, the value of South Korea's iron ore imports retreated by an average % from all supplying countries since 2014 when iron ore purchases were valued at billion.

Iron ore, which is used to make steel, accounts for nearly 70 percent of Vale's revenue and around 80 percent of its earnings. Among the steel stocks with high market cap value, Vale remains the only one which generated positive returns of a little over 3 percent in 2018.

Preamble. Whereas the production of iron ore pellets involves the mining of iron ore from open pits, crushing and concentrating the ore into a concentrate, and finally pelletizing. In the pelletizing process, iron ore concentrate is rolled into balls (pellets) and hardened through .

Iron Ore Processing For The Blast Furnace . Processing facility located on the mesabi iron range of minnesota creating steel from lowgrade iron ore requires a long process of mining crushing separating concentrating mixing pelletizing and shipping the process of mining low grade iron ore or taconite requires massive resources heavy industrial

bentonite powder used in iron palletising plant. Bentonite Powder Used In Iron Palletising Plant Bentonite Powder Used In Iron Palletising Plant Iron ore pelletizing Iron ore pelletizing Iron ore fines are agglomerated into, pelletizing plants have a faster start up, dolomite as a fluxing agent and bentonite, bentonite processing procedure YouTube

iron ore beneficiation capacity Iron ore Wikipedia. · Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities.

Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled. ironmaking products, fluxes, slagforming agents, and solid fuel (coke). The purpose of the sintering. process is manufacturing a product with the suitable characteristics (thermal, mechanical, physical and.

Iron Ore Processing Plant DesignSmall Stone Crushing ... The iron ore processing plant design, on the one hand, must comply with the national regulations on the design and treatment of urban iron ore processing plants, requiring the design of iron ore processing plants to have environmental and energysaving performance; on the other hand, considering iron ore processing The plant is designed ...

Iron ore is the source of primary iron for the world's iron and steel industries. It is therefore essential for the production of steel, which in turn is essential to maintain a strong industrial base. Almost all (98%) iron ore is used in steelmaking. Iron ore is mined in about 50 countries.

is the best resource for Steel News, Metal/Mining News, Coal/Power News, gasoil News, infrastructure/logistics news, automobile news and provides historical data for Raw Materials ...

Aug 06, 2018· Table 5: Iron Ore Pricing Scenario (): Historic and Recent Past Average Prices of Iron Ore in US per Dry Metric Ton (includes corresponding Graph/Chart) Global Iron Ore .

Each iron making furnace has specific iron ore pellet chemistry requirements that govern the design criteria of an iron ore pelletizing plant. ''s equipment, parts and services for pelletizing process are designed to increase capacity, reduce fuel and power consumption, and cut maintenance costs.